Introduction to the characteristics and uses of Drum Filter

By: Kate Nana

Post Date:April 29th, 2025

Post Tags: Drum Filter :Introduction to the characteristics and uses of Drum Filter

Drum Filter, also known as fully automatic Drum Filter, is a drum-type screen filter device, which is mostly used for mechanical equipment for solid-liquid separation in the early stage of sewage treatment systems.

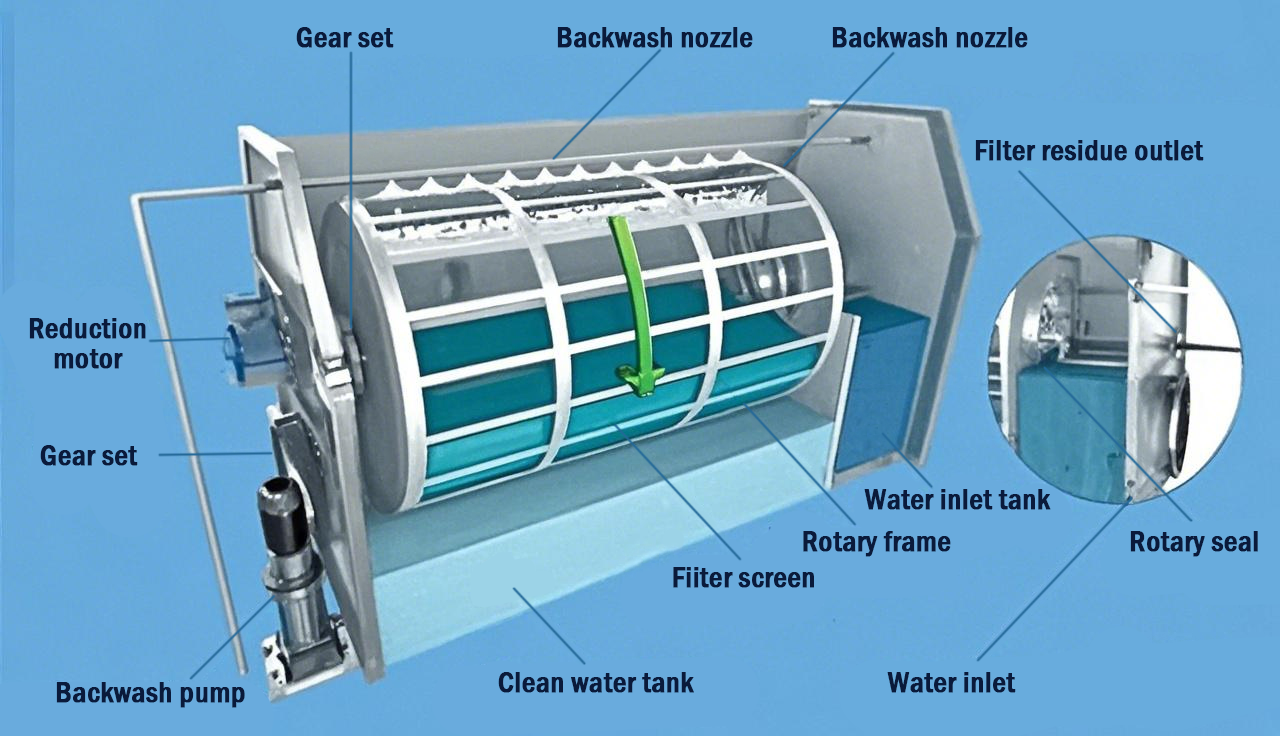

The drum is equipped with a filter screen. When the drum is placed in water for operation, 2/5 of the filter screen is immersed in the water. The treated wastewater enters the drum along the axial direction and flows out through the screen. The impurities in the water (fine suspended matter, fiber, pulp, etc.) are retained on the inner surface of the filter screen on the drum. When the impurities retained on the filter screen are brought to the upper part by the drum, they are flushed into the sewage tank by the backwash water on the outside of the screen to achieve solid-liquid two-phase separation. The backwash is controlled by a timer or liquid level sensor. The filtered water flows back to the pool for recycling. The rotation of the Drum Filter is driven by hydraulic power and operates continuously and automatically.

Working principle

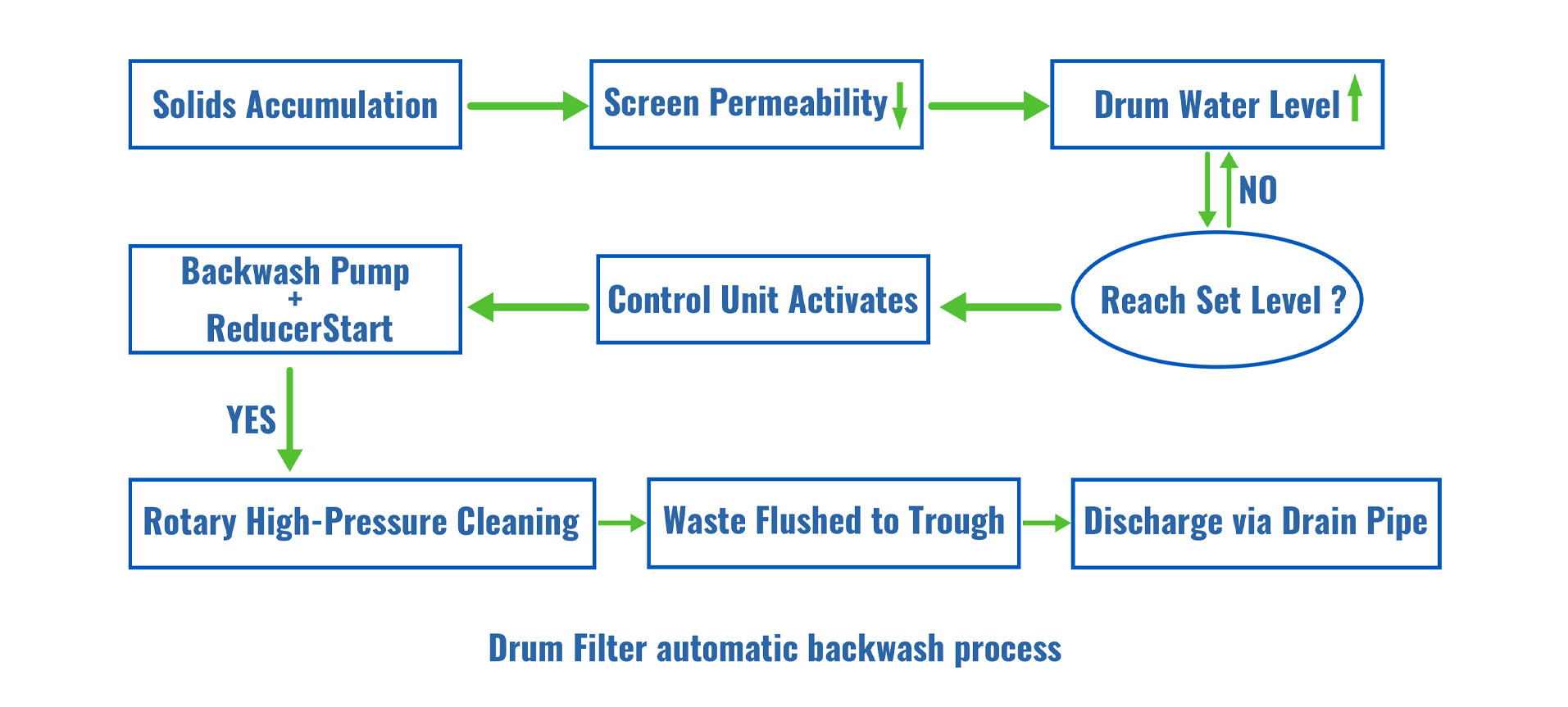

When the Drum Filter enters the working state, when water containing suspended particles enters the Drum Filter, the suspended matter will be retained by the stainless steel filter screen, and the water without suspended matter after filtration enters the reservoir. When the suspended matter in the drum of the Drum Filter accumulates to a certain amount, it will cause the water permeability of the filter to decrease, causing the water level in the drum to rise. When the water level rises to the set high water level, the liquid level automatic control system works. At this time, the backwash water pump and the drum motor are automatically turned on at the same time. The high-pressure water of the backwash water pump is used to high-pressure clean the rotating drum filter through the backwash system of the Drum Filter. The suspended matter blocked on the drum filter flows into the dirt collection tank under the flushing of high-pressure water and then discharged through the sewage pipe. When the filter is cleaned, the water permeability of the drum filter increases and the water level in the drum decreases. When the water level drops to the set low water level, the backwash water pump and the drum motor will automatically stop working, and the Drum Filter enters a new round of working cycle.

Equipment features

1. Durable: The filter screen adopts a stainless steel filter, which has strong anti-corrosion performance and long service life.

2. Good filtration performance: The stainless steel filter of this equipment has the characteristics of small pore size, low resistance, strong water passing capacity, and high filtration capacity for suspended matter.

3. High degree of automation: The equipment has an automatic backwashing function, which can ensure that the equipment works normally.

4. Low energy consumption, high efficiency, easy operation and maintenance.

5. Exquisite structure and small footprint.

Equipment use

1. Applicable to the early solid-liquid separation of sewage treatment system.

2. Applicable to the early solid-liquid separation treatment of factory circulating water treatment system.

3. Applicable to industrial and major farm wastewater treatment links.

4. Widely used in various occasions where solid-liquid separation is required.

5. Microfiltration equipment for factory farming.

Practical application

In the field of aquaculture, Drum Filter is more used in the first stage of raw water filtration to filter out large particles of sediment, suspended algae, particles, etc. in the water. Or it is used in the first stage of coarse filtration in closed circulation purification.