Magnetic Bearing Blower vs Air Foil Bearing Blower: A Technical Comparison

By: Kate Nana

Post Date: October 27th, 2025

Email:Kate@aquasust.com

Post Tags: Blower Maintenance,Magnetic Bearing Blower ,Air Foil Bearing Blower,Aquasust Air Suspension Blower

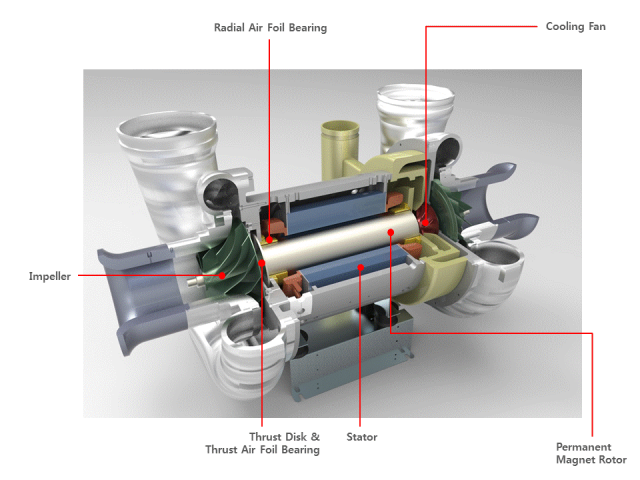

Both the Magnetic Bearing Blower and the Air Foil Bearing Blower are single-stage centrifugal blowers. Their core technologies incorporate non-contact bearings, high-speed permanent magnet motors, and variable frequency drive speed control. Both can achieve an oil-free lubrication system and are characterized by high efficiency, energy savings, low noise, and freedom from oil pollution.

However, there are distinct differences between them, primarily in the type of non-contact bearing used. The Magnetic Bearing Blower utilizes active magnetic bearings, which levitate the rotor through electromagnetic force. In contrast, the Air Foil Bearing Blower employs air foil bearings. Its operating principle relies on the aerodynamic effect: when the blower rotor rotates at high speed, a dynamic pressure effect is generated between the rotor and the surface of the foil bearings, forming a high-pressure air film that lifts and suspends the rotor. It's important to note that Air Foil Bearing Blowers have higher environmental requirements. The installation site must be dust-free and uncontaminated, and adequate air filtration is necessary to prevent operational failures.

General Maintenance Principles for Magnetic/Air Foil Bearing Blowers:

Regular Inspection: Conduct periodic inspections and maintenance on the blower to ensure normal equipment operation. This includes checking the operating status of the suspension bearings, the control system's performance, and the condition of the pneumatic components.

Cleaning Maintenance: Keep the blower's exterior clean. Regularly remove dust and debris from the blower surface, and prevent water and corrosive liquids from splashing onto the unit.

Lubrication Maintenance (Primarily for Magnetic Bearings): Perform regular lubrication maintenance on magnetic bearings to ensure the bearing surfaces remain smooth, minimizing unnecessary friction and wear. Simultaneously, replace the lubricating grease on the bearings periodically to ensure their normal operation. (Note: Air foil bearings typically do not require liquid lubrication in the same way, relying on the air film).

Environmental Protection: Install the blower in a dry, dust-free, non-corrosive, and explosion-proof environment to reduce damage and contamination to the unit.

Electrical System Check: Regularly inspect the blower's electrical system, including power lines, the contact condition of terminals, and the operational status of all sensors. Promptly repair or replace any components if abnormalities are found.

Common Issues and Solutions:

Excessive Rotor Friction: Possible causes include bearing malfunctions or poor lubrication. The solution is to inspect the bearings and perform timely repairs or replacements.

Unstable Airflow/Output: This may be caused by electrical system faults. The solution is to inspect the electrical system and repair the malfunction.

Routine Maintenance

Essentially involves replacing the filter cotton and filters.

To ensure the output air is clean and guarantee the safe, stable, and long-term operation of the motor and electrical components, two-stage filtration (primary filter cotton and medium-efficiency filters) is installed at the process air intake and cooling air intake points.

During operation, regularly check the inlet filters for clogging. Severe clogging can lead to excessive pressure differentials inside and outside the enclosure, resulting in adverse phenomena such as motor overheating, reduced blower efficiency, and surge.

It is recommended to replace the primary filter cotton monthly. Failure to replace it promptly will shorten the service life of the medium-efficiency filters. Medium-efficiency filters should be replaced every 2-3 months. The specific replacement interval should be determined based on the local air dust concentration.

Sample Content