Reasons and Solutions for Sludge Floating in Inclined Tube Settling Tanks

By: Kate Nana

Post Date:April 9, 2025

Post Tag:Reasons and Solutions for

Sludge Floating in Inclined Tube Settling Tanks

I. Causes of Floc Floating

1.High Algae Content in Raw Water

Organic matter produced by algal metabolism affects coagulation and filtration. Acidic substances in the organic matter react with hydrolysis products of coagulants (iron or aluminum salts), forming surface complexes that adhere to floc particles, hindering particle collisions. If floc floating persists in winter or under conditions unsuitable for algae growth, this factor can be ruled out.

2.Improper Sludge Discharge or Equipment Malfunction

Failure to discharge sludge promptly or thoroughly in inclined tube settling tanks can lead to excessive floc accumulation beyond the tank's capacity.

Additionally, if the scraper malfunctions and stops during operation, floc floating becomes noticeably severe.

3.Difficulty in Controlling Coagulant Dosage

Colloidal substances in raw water do not settle naturally. Coagulants are added to destabilize these colloids, forming larger flocs for natural settling and subsequent treatment.

However, if operators fail to adjust coagulant dosage based on influent quality, coagulation becomes insufficient, resulting in poorly settling flocs.

This manifests in two ways:

·Excessive coagulant compresses the double electric layer of particles, promoting collisions and growth, causing flocs to adhere to bubbles and float.

·Insufficient coagulant fails to effectively compress the double electric layer or promote floc growth, reducing bubble adhesion efficiency and preventing effective flotation.

4.Excessive Hydraulic Load

When particle settling velocity equals the upward flow rate, a visible clear-turbid interface forms in the inclined tubes, with a lower suspension zone where flocs intercept fine particles until they grow large enough to settle.

If water demand increases and the plant operates overloaded, the flow velocity in the inclined tubes rises, hindering floc settling and carrying them into the clear water zone, where they deposit on the upper tubes.

5.Influence of Raw Water Turbidity

·High turbidity: Forms dense, coarse flocs with limited bubble adhesion, requiring higher coagulant doses.

·Low turbidity: Fewer colloidal particles reduce collision and coagulation opportunities, leading to poor coagulation. In such cases, coagulant dosage must not be too low.

Notably, floating flocs often carry micro-bubbles on their surfaces and pores, caused by:

·Anaerobic fermentation of sludge at the tank bottom: Incomplete sludge discharge leads to sludge accumulation and compaction, producing gases like methane, CO₂, and traces of H₂S.

·Algal activity: Intense respiration and photosynthesis generate observable gas production.

·Pump and pipeline leaks: Includes pump body leaks, suction pipe air intake, or suction pipe leaks.

II. Solutions for Floc Floating

1.Optimize Sludge Discharge Timing

Install an additional sludge collection trough along the effluent side with perforated suction pipes linked to the scraper. When sludge is pushed to the trough edge, it flows into the trough, and opening the discharge valve removes diluted sludge. Adjust discharge timing based on raw and effluent water quality.

2.Add Clay for Low-Turbidity Water

Adding clay increases particle concentration, enhancing collision and coagulation efficiency. This is a low-effort solution. Alternatively, use dosing pumps to add coagulant aids like PAM.

3.Control Coagulant Dosage

As mentioned, adjusting coagulant dosage can suppress floc floating, which often occurs during low-turbidity periods.

To prevent "air binding" in filters due to gas-saturated water, consider:

·Direct filtration after micro-flocculation in the reaction tank.

·Pre-filtration aeration and direct dosing before filtration.

·Use SCD (Streaming Current Detector) for real-time coagulation monitoring. SCD measures streaming current, compares it with set values, and adjusts coagulant dosage via mathematical models for optimal results.

4.Address High Hydraulic Load with Split-Tank Operation

During full-load operation, open inter-tank valves to balance inflow and prevent overload. Coordinate inflow scheduling to minimize fluctuations and stabilize effluent quality.

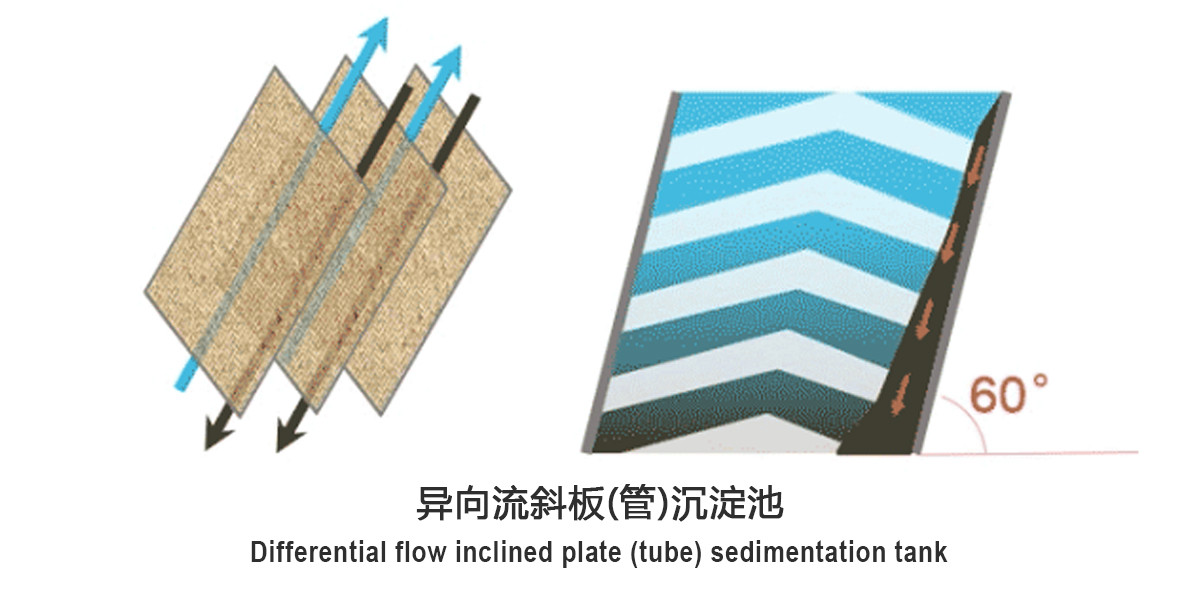

5.Convert to Counter-Flow Inclined Tube Flotation-Sedimentation Tank

Given variations in turbidity, algae, and organic matter, retrofit existing inclined tube tanks into counter-flow flotation-sedimentation tanks. Use sedimentation for high turbidity and flotation for low turbidity.