Tube Settler Maintenance and Cleaning

By: Kate Nana

Post Date: June 24th, 2025

Email:Kate@aquasust.com

Post Tags: Tube Settler, Secondary Wastewater Treatment, WastewaterSolutions,tube settler customized

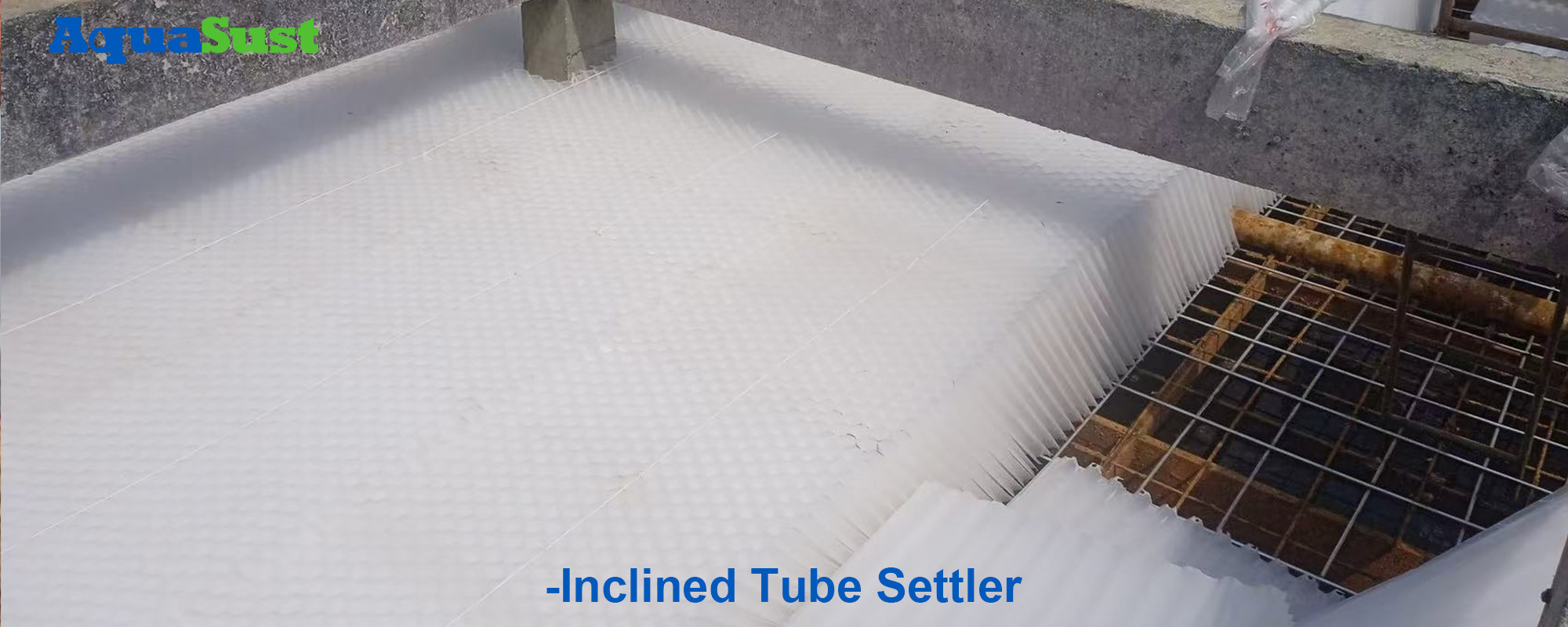

Tube settlers are primarily used for various sedimentation and sand removal purposes. They have been one of the most widely adopted and mature water treatment equipment in water supply and drainage engineering over the past decade. Featuring a wide application range, high treatment efficiency, and small footprint, they are suitable for sand removal at water inlets, sedimentation of general industrial and domestic water, and oil separation. They are applicable to both new projects and retrofitting existing old tanks, yielding good economic benefits.

Honeycomb tube settlers packing also has a wide range of uses. In many sewage treatment industries, honeycomb tube settlers packing is used for sedimentation treatment of sewage. Polypropylene honeycomb tube settlers packing is generally selected, which is free of variegation, environmentally friendly, effective, and has a certain inclination. This honeycomb tube settlers packing has a wide application range, good treatment effect, and small floor space. It is suitable for water treatment in water-sand systems, sedimentation of general industrial and domestic water, and oil separation treatment. Honeycomb tube settlers packing is suitable for both new constructions and retrofitting existing old tanks, with good economic benefits. Today, let's talk about how to clean the tube settlers packing in the sedimentation tank!

I. Methods for Cleaning Sludge on Tube Settlers in Sedimentation Tanks

1. Hydraulic Flushing Method (Commonly Used)

-Principle: Use high-pressure water flow to impact the surface of tube settlers, dispersing the sludge and discharging it with the water flow.

-Operation Steps:

①Pause water inlet and lower the water level in the sedimentation tank to 20–30 cm above the tube settlers (to avoid the impact of too deep water on flushing efficiency).

②Use a high-pressure water gun (generally with a pressure of 3–5 MPa) to spray at a 45° angle from above or the side of the tube settlers, flushing the surface row by row.

③The flushing direction should be consistent with the inclination direction of the tube settlers (typically 60°) to facilitate the sludge sliding to the bottom of the tank with the water flow, which is then discharged through the sludge discharge system.

-Application Scenarios: Suitable for light sludge (such as algae and loose sludge) during regular maintenance.

2. Mechanical Cleaning Method

-Principle: Manually or automatically remove stubborn sludge on the surface of tube settlers through mechanical devices (such as sludge scraping boards or brushes).

-Operation Modes:

①Manual cleaning: Workers enter the tank wearing protective gear and gently scrape the surface of tube settlers with soft brushes or plastic sludge scraping boards to avoid damaging the tube settlers material.

②Automatic cleaning: Some sedimentation tanks are equipped with movable mechanical arms or rotating brushes, which are driven by motors for regular cleaning of tube settlers (needs to be customized according to equipment design).

-Precautions: Avoid using metal tools during mechanical cleaning to prevent scratching the tube settlers (especially plastic materials).

3. Chemical Cleaning Method (for Stubborn Sludge)

-Principle: Use chemical reagents to dissolve or disperse the viscous substances (such as grease and biofilm) in the sludge.

-Operation Steps:

①Prepare a cleaning agent with appropriate concentration (such as sodium hypochlorite solution for sterilization and algae removal, sodium hydroxide solution for grease removal, or special cleaning agents).

②Evenly spray the cleaning agent on the surface of tube settlers through a sprinkler system, soak for 15–30 minutes, and then remove the sludge with the hydraulic flushing method after it softens.

-Precautions:

①Confirm the corrosion resistance of tube settlers material before chemical cleaning (e.g., polypropylene (PP) tube settlers have better acid and alkali resistance, followed by polyethylene (PE)).

②Thoroughly rinse with clean water after cleaning to avoid reagent residues affecting subsequent water quality.

4. Backwashing Method (Suitable for Modular Tube Settlers)

If the tube settlers are of modular design (such as integrated tube settlers components), self-cleaning can be achieved through reverse water flow (flushing upward from below the tube settlers). During operation, briefly turn on the backwashing pump and control the flow rate to avoid overturning the tube settlers, which is suitable for sedimentation tanks designed with a backwashing function.

II. Maintenance Points for Aquasust Tube Settlers

1. Daily Inspection

-Regularly observe the sludge amount on the surface of tube settlers, as well as the growth of algae or blockage by foreign objects.

-Check whether the fixing devices of tube settlers (such as brackets and buckles) are loose to prevent displacement or collapse of tube settlers.

2. Regular Cleaning Cycle

-Mild pollution (municipal sewage): Hydraulic flushing once every 2–4 weeks.

-Severe pollution (industrial wastewater): Cleaning once every 1–2 weeks, combined with chemical cleaning if necessary.

-Shorten the cleaning interval during the algae reproduction period in summer.

3. Material Maintenance

-Confirm the material of Aquasust tube settlers (commonly PP or PE), and avoid contact with strongly corrosive substances (such as concentrated acids and alkalis).

-If the surface of tube settlers shows aging, embrittlement, or damage, promptly replace local or overall components (contact the supplier for accessories).

4. Measures to Prevent Biological Attachment

-Regularly add a small amount of fungicide (such as sodium hypochlorite, concentration 1–3 mg/L) to inhibit the growth of algae and microorganisms.

-For high-organic wastewater, reduce sludge viscosity by adjusting the front-end process (such as adding pretreatment).

5. Anti-freezing in Winter

If the sedimentation tank operates in a low-temperature environment, prevent ice formation between tube settlers:

-Maintain continuous water flow operation to avoid long-term shutdown.

-Insulate the tube settlers area when necessary (such as covering with thermal insulation materials).

III. Precautions

1. Safe Operation

-Ventilate the sedimentation tank and detect the oxygen content in the tank (not lower than 19.5%) before entering to avoid hypoxia or harmful gas poisoning.

-Wear non-slip shoes, safety helmets, and other protective equipment to prevent slipping or falling.

2. Equipment Protection

-Avoid direct water flow impact on the edges of tube settlers during flushing to prevent component detachment.

-Act gently during mechanical cleaning, especially as plastic tube settlers are easily damaged by external force.

3. Record and Summary

-Record the time, sludge amount, and used reagents/methods after each cleaning and maintenance to facilitate analyzing the sludge amount change trend and optimizing the maintenance cycle.

Custom Tube Settler AS-25PP | 25mm Lamella Design for Municipal & Hospital Wastewater Solution

Tube Settler AS-35PP Superior shock and corrosion resistance for efficient secondary treatment of textile and dyeing wastewater

AS-50PP Tube Settler: Optimize Your Pulp & Paper Wastewater Treatment with Low Energy Consumption and Operating Costs.

Enhance your wastewater treatment efficiency with our OEM Supplier Tube Settler AS-80PP. Easy installation, easy maintenance.